Steam traps are vital components in steam heating systems, ensuring the efficient and effective operation of these systems by managing the removal of condensate and non-condensable gases while retaining valuable live steam. This article explores the various types of steam traps, their functions, applications, and the importance of their maintenance and monitoring.

Types of Steam Traps

Steam traps come in several varieties, each suited to specific operational needs and environments. The main types are:

Mechanical Traps: These traps utilize the density difference between steam and condensate to function. The two common mechanical traps are:

- Float Traps: Operate using a float mechanism that rises and falls with the condensate level, opening and closing a valve accordingly.

- Inverted Bucket Traps: Feature an inverted bucket that floats when steam is present and sinks when only condensate is present, thereby operating a valve mechanism.

Thermostatic Traps: These traps respond to temperature changes to control the valve:

- Bellows-Type Thermostatic Traps: Utilize a bellows filled with a fluid that expands and contracts in response to temperature changes, opening or closing the valve.

- Bimetallic Traps: Use bimetallic strips that bend when subjected to temperature changes, thereby controlling the valve mechanism.

Thermodynamic Traps: Rely on the difference in velocity between steam and condensate:

- Disc-Type Thermodynamic Traps: Employ a disc that moves between a seat and the cap, influenced by the pressure and temperature of steam and condensate.

Functions of Steam Traps

Steam traps play several crucial roles in steam heating systems:

- Condensate Removal: They efficiently remove water formed from condensed steam, preventing water hammer and ensuring optimal heat transfer.

- Air Venting: By expelling non-condensable gases and air from the system, steam traps help maintain efficient heat transfer.

- Energy Conservation: Steam traps prevent the loss of live steam, thereby conserving energy and reducing operational costs.

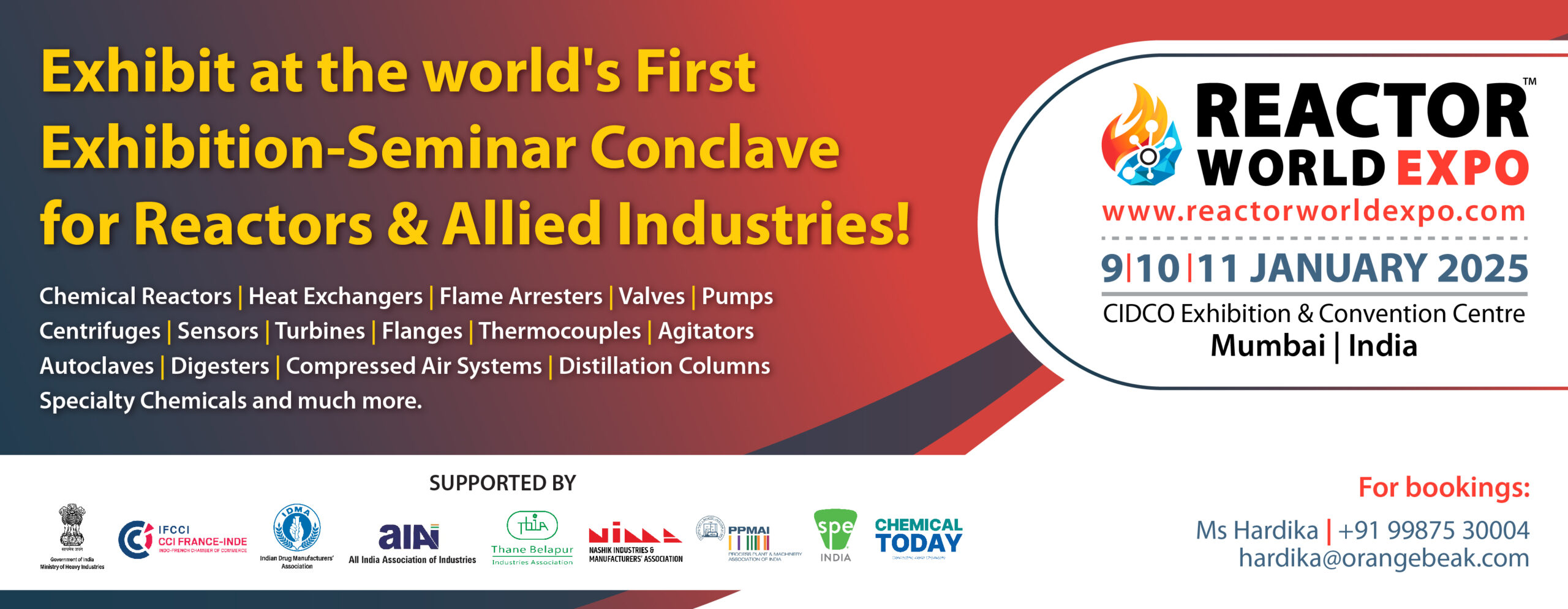

Applications

Steam traps are indispensable in a wide range of industries and applications, including:

- Heating Systems: Used in radiators, convectors, and other steam heating units to maintain efficient operation.

- Steam-Using Equipment: Integral to the functioning of heat exchangers, steam cookers, autoclaves, and other steam-powered devices.

- Steam Distribution Systems: Essential for removing condensate from steam lines, preventing water hammer, and ensuring system efficiency.

Maintenance and Monitoring

Regular maintenance and vigilant monitoring of steam traps are critical to sustaining the efficiency and longevity of steam systems. Key maintenance tasks include:

- Blow-Through Detection: Identifying and repairing traps that allow continuous steam passage.

- Blocked Trap Identification: Ensuring traps open correctly to prevent condensate backup.

- Leakage Prevention: Addressing traps that intermittently leak steam.

Effective steam trap management can lead to significant energy savings and improved performance. Regular inspections help detect and rectify issues promptly, ensuring the system operates at peak efficiency.

Conclusion

Steam traps are essential for the proper functioning of steam heating systems, playing a pivotal role in maintaining efficiency, conserving energy, and preventing damage. By understanding the different types of steam traps, their functions, and the importance of their maintenance, industries can optimize their steam systems for better performance and cost-effectiveness. Regular maintenance and vigilant monitoring ensure that steam traps continue to perform their critical functions, contributing to the overall efficiency and reliability of steam heating systems.