Introduction:

In the era of Industry 4.0, digitalization has become a transformative force in the field of chemical engineering. The integration of advanced technologies, data analytics, and smart manufacturing processes is reshaping how chemical plants operate, offering unprecedented efficiency, flexibility, and insights.

Smart Manufacturing and Real-Time Monitoring:

Digitalization in chemical engineering involves the implementation of smart manufacturing technologies that enable real-time monitoring of processes. Sensors and IoT devices collect data, providing operators with instant insights into various parameters, allowing for proactive decision-making and process optimization.

Artificial Intelligence and Machine Learning:

Artificial intelligence (AI) and machine learning (ML) algorithms are revolutionizing chemical engineering by analyzing vast datasets to identify patterns, predict equipment failures, and optimize production processes. Predictive maintenance, quality control, and energy efficiency are areas where AI and ML are making significant impacts.

Supply Chain Integration and Connectivity:

Industry 4.0 emphasizes the connectivity of entire value chains. In chemical engineering, this means integrating suppliers, manufacturers, and distributors through digital platforms. Such integration enhances collaboration, streamlines logistics, and allows for dynamic adjustments based on real-time demand and supply fluctuations.

Digital Twins for Process Simulation:

The concept of digital twins involves creating virtual replicas of physical processes. In chemical engineering, digital twins enable accurate simulations of production processes, facilitating the identification of potential issues and the testing of various scenarios without disrupting actual operations. This technology enhances process reliability and optimizes performance.

Cybersecurity and Data Integrity:

As digitalization progresses, the importance of cybersecurity and data integrity cannot be overstated. Chemical plants must implement robust cybersecurity measures to protect sensitive data and ensure the reliability of digital systems. Securing digital assets is crucial for maintaining the integrity of processes and preventing cyber threats.

Human-Machine Collaboration:

Industry 4.0 recognizes the significance of human-machine collaboration. In chemical engineering, this translates to operators working alongside intelligent machines and systems. Advanced interfaces and augmented reality tools empower operators to make informed decisions, leveraging the insights provided by digital technologies.

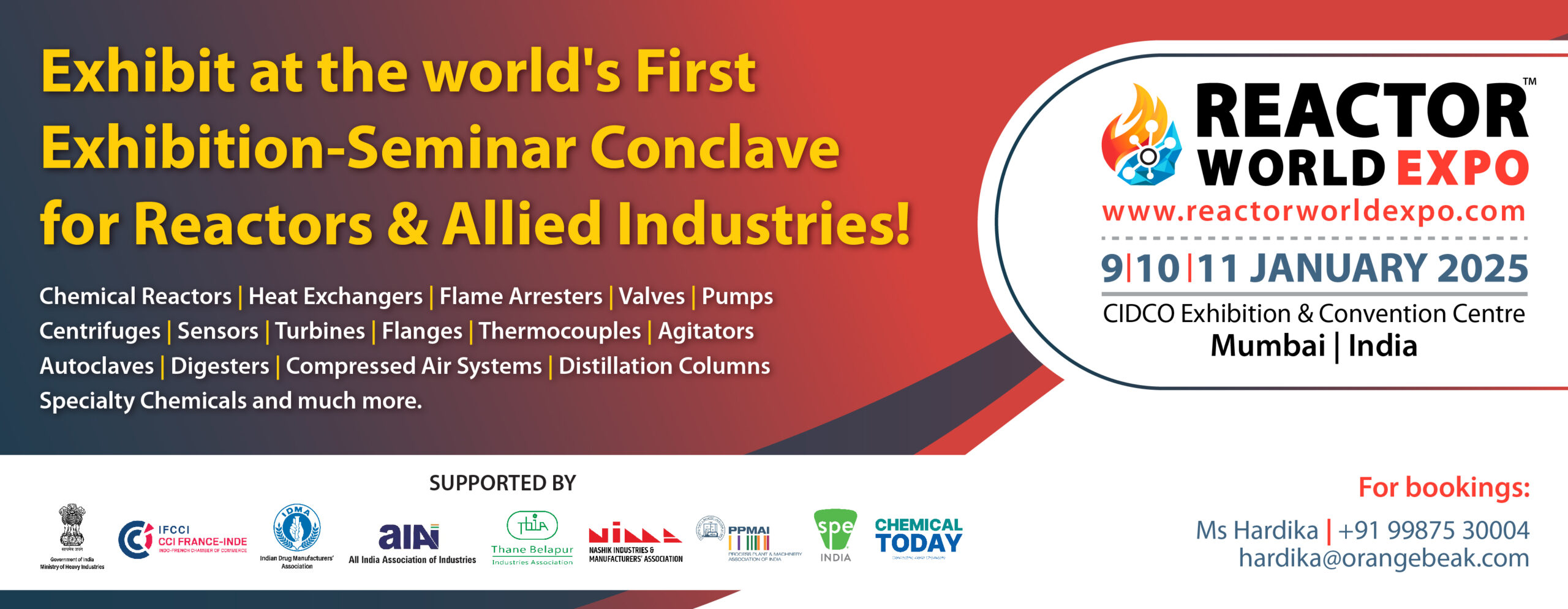

Case Studies:

Notable examples of successful digitalization in chemical engineering include the implementation of advanced process control systems, the use of AI for predictive maintenance, and the adoption of blockchain technology to enhance transparency in the supply chain.

Future Prospects:

The journey of digitalization and Industry 4.0 in chemical engineering is an ongoing evolution. As technologies continue to advance, the industry can expect further integration of smart systems, increased automation, and a more interconnected and efficient ecosystem.

Conclusion: Digitalization and Industry 4.0 have ushered in a new era for chemical engineering, offering unprecedented opportunities for efficiency, sustainability, and innovation. As the industry continues to embrace these technologies, the future holds exciting possibilities for smart, connected, and agile chemical manufacturing process.